A major producer of primary aluminium

in Europe

Our raison d’être

Sustainably producing low carbon aluminium in France for new consumer modes and mobility to create a world that is more respectful of the planet and those who live on it.

Our process

The aluminium production process

from bauxite to metal

Our site

A constantly expanding

production site

Aluminium Dunkerque covers

65 hectares at the heart of the Grand Port Maritime de Dunkerque

close to the Gravelines nuclear power station which meets the company’s strategic needs for low carbon energy.

From the outset in 1991,

Aluminium Dunkerque was at the cutting edge of technology, but also in terms of architecture, work organisation and respect for the environment. Innovating and designed to minimise its impact

the plant was one of the most visited French industrial sites

when it was first built.

Created as part of a strategy to revitalise a declining industrial area,

Aluminium Dunkerque is perfectly integrated into its local area and today continues to contribute to the revival of the Dunkirk region,

in particular through its ambitious project to decarbonise its activity. It is the last major aluminium plant project to be developed in France.

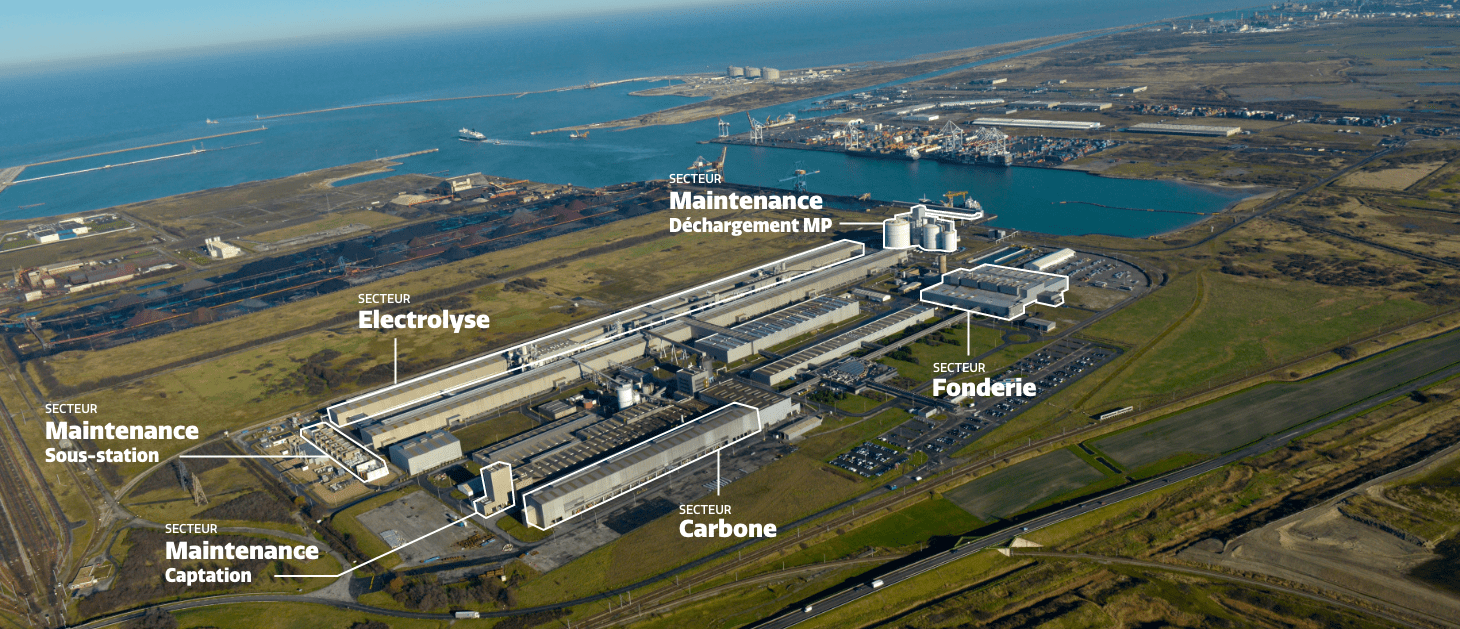

Our sectors

The site has three main production zones and a maintenance sector.

The Carbon sector produces the anodes used on site during the electrolysis process.

The materials used include pitch and coke, as well as recycled anodes.

the anodes are produced in 3 workshops:

- Paste workshop

- Baking furnace

- Sealing workshop

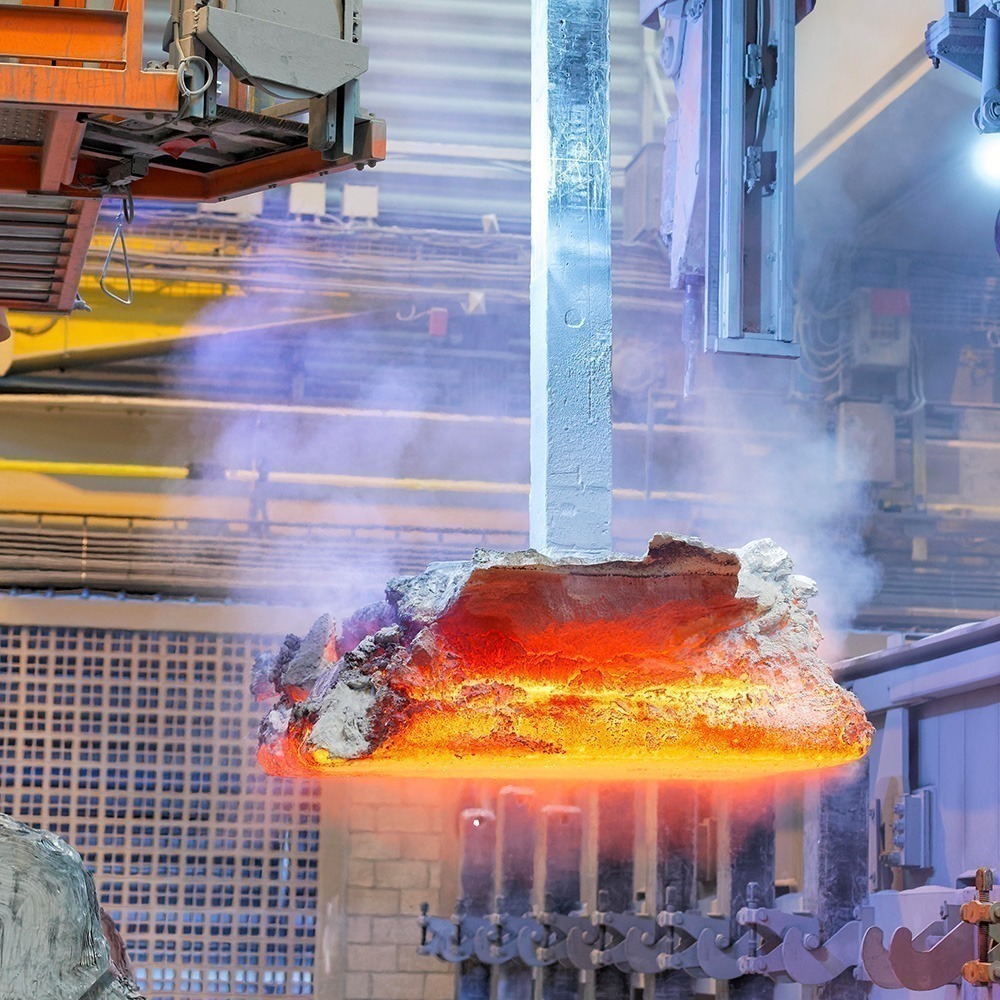

The Electrolysis sector produces the primary aluminium, which is processed into slabs and ingots.

The aluminium is produced in two 850-metre-long halls, in 264 electrolysis pots.

The Foundry sector receives molten aluminium from the Electrolysis sector and casts both slabs, using the Vertical Continuous Casting method for the rolling industry, and alloy ingots for the automotive sector.

4 casting machines and 7 furnaces (capacity of 300 kt/year) slabs (80%) and ingots (20%)

The Maintenance sector maintains and operates the site’s utilities:

- Unloads raw materials,

- Operates the gas processing centre, supplies energy (electricity, air, water),

- Ensures that equipment complies with regulations,

- Manages IT and regulation systems,

- Designs and implements industrial projects, ..

The strengths of an advantageous geographical location

A deep water port for raw material supply.

A set of communication routes

(sea, rail, road).

A real local potential of qualified skills.

A well established industrial tradition

.

The proximity of the Gravelines nuclear power station producing low carbon electricity…

Our key figures

+10

countries of exportation

700+

Employees

65 ha

surface area

+€800m

turnover

300k

tonnes of aluminium produced/year

+€50m

annual investments

A strong technological base

Aluminium Dunkerque has upgraded its Aluminium Pechiney technology to reach over 400kA.

The power is currently at 390 kA, which is the best compromise between efficiency and energy savings in the current context.

Aluminium Dunkerque regularly invests to optimise its technology and has thus increased its production capacity by over 40% since it began producing.